About GSI Flow Calculation Software

GSI’s fire system design software has been used to successfully design thousands of fire suppression systems worldwide. For over 40 years, GSI has provided design software for fire suppression systems which use clean agents and carbon dioxide. More recently, GSI developed software to design the first fully engineered industrial dry chemical systems.

GSI software for halocarbon agents such as HFC-227ea, HFC-125, HFC-23, FK-5-1-12, for inert gas agents such as IG-100, IG-01, IG-55, IG-541, for high pressure and low pressure carbon dioxide, and for engineered dry chemical is available.

Most of the US manufacturers of clean agent and carbon dioxide system use customized software developed by GSI. Worldwide, GSI has developed custom software for manufacturers based in the United States, Canada, UK, Denmark, South Korea, Japan, Australia, Italy, and Spain.

GSI works with system manufacturers to obtain listings and approvals of flow calculation software. UL, FM, KFI, Vds, FPA, and ULC are among the agencies which have approved software developed by GSI. GSI can provide complete approval testing or will work the manufacturers who wish to do testing in their own laboratories.

GSI pioneered remote verification of flow testing to enable our clients to complete their projects during the COVID lockdowns which were in effect in some countries. Now, remote verification continues to be used by companies wishing to minimize travel expenses associated with “in person” approval testing.

Below you can see the various standard and custom features of GSI flow calculation software. You will also find information on how to begin a development project with GSI.

Standard Features

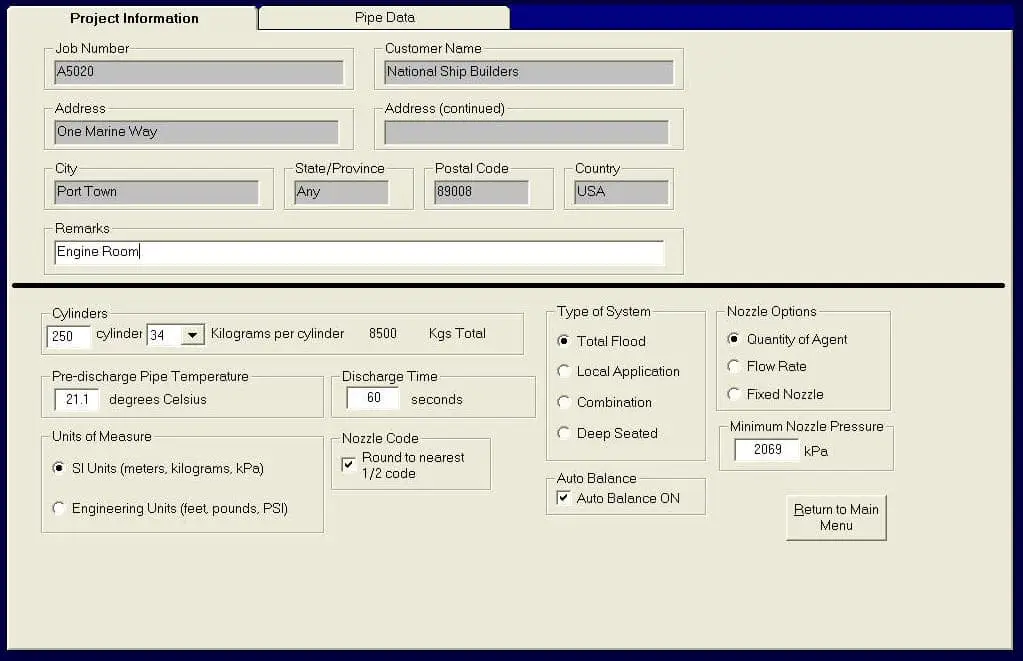

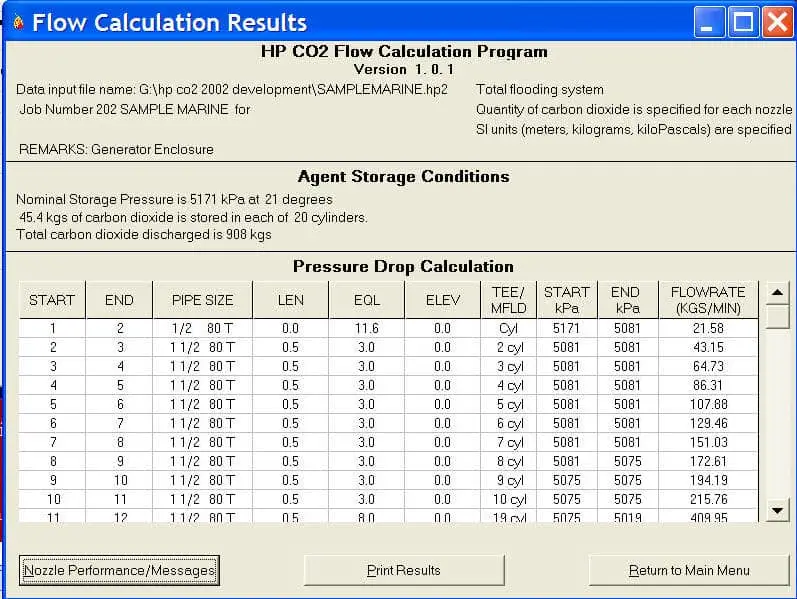

- Calculates pipe size and nozzle size to deliver required flow of agent and discharge time

- For existing systems, calculates flow of agent and discharge time based on fixed pipe and nozzle sizes as installed

- Verifies sufficient pipe wall thickness to contain predicted system pressures

- Estimates required enclosure venting for clean agent systems

- Calculates residual oxygen values for inert gas systems

- Optional calculation of agent quantity requirements

- Halocarbon agent storage pressures from 20 bar to 70 bar or more

- Inert gas storage pressures from 150 bar to 300 bar or more

- High and low pressure carbon dioxide storage as well as custom storage temperature/pressure conditions

- Choice of units (SI, Eng)

- Customized to comply with various standards: NFPA, ISO, KFI, etc.

OEM Features

- OEM Logos

- Custom cylinder capacities

- OEM valve characteristics – size, equivalent length

- Storage pressure per customer specification

- Fill densities per customer specification

- Pressure reduction device characteristics corresponding to OEM hardware (inert gas)

- Optional bill of materials

- Other features per customer requirements

- Agency approvals per customer requirement

For more information on system development services (software and/or hardware development), please submit the form below or call our development office at 1-219-213-1440. Thank you for your interest!